History

QUALITY PRODUCTS & SERVICES SINCE 1890

Beginning in 1890, “Customer Satisfaction Through Quality Products & Services” was Wilson Trailer Company’s guiding principal. Wilson maintains this same commitment today, and as we look into the future. Our daily company-wide dedication of planning excellence into every detail propels Wilson Trailer to the top of our industry and be known for our quality products in North America and around the world.

Wilson Trailer has made wise use of corrosion-resistant aluminum over the years and has expertly applied the material into the right areas of its trailer construction. Wilson trailers are well known for their ability to haul a larger payload, have amazing performance, and last much longer with lower maintenance costs. With their renowned service-after-the-sale added in, Wilson Trailer believes they are providing their customers with the industry’s very best value.

Today, Wilson Trailer Company maintains headquarter offices in Sioux City, Iowa and operates four modern production plants in Yankton, South Dakota; Moberly, Missouri; Lennox, South Dakota and Sioux City, Iowa. Family owned since its origin, Wilson Trailer is guided by the fourth generation of this family and the fifth generation is poised for future company leadership. It is their intent to carry out the Wilson legacy and the goal of being a worldwide leader in the design, manufacture, and marketing of transportation products.

Wilson is a good name to have behind you!

You can follow Wilson Trailer’s progression through the years by traveling down the timeline and different eras below.

A daring young Frank T. Wilson ventured into the Dakota Territory with two loads of carriage and wagon stock to set up shop with a business partner. Seven years later, Frank took his talents to Sioux City, joining his brother George in forming what would become the Wilson Trailer Company of today. Together, they built a thriving enterprise.

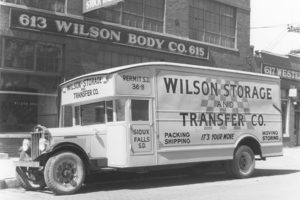

The automobile and truck are no longer just “passing fads.” Frank Wilson is quick to establish a business, which builds not only truck bodies, but protective cabs, as well. The truck transportation industry begins to boom. And so does Wilson Trailer Company.

Frank’s bright young son-in-law, Clarence Persinger, joined the company. He brought with him what was to become a new generation of exciting ideas. In the1930’s, properties were purchased, adjoining the original Wilson plant. This additional space would make possible the first Wilson Trailer production line. In the late 30’s, with Clarence Persinger now at the helm, Wilson Trailer began production of custom-designed sleeper buses for some of the most popular bands in the country.

Wilson Trailer was among the original group of truck and trailer manufacturers that formed what has come to be known as the Truck Trailer Manufacturers Association headquartered in Washington, D.C. The TTMA was founded as the voice for people associated with the business of hauling goods and to promote the interests of the motor transport and truck trailer industry. Later, it was Wilson Trailer Company under the leadership of Clarence Persinger who developed and popularized the “frameless” trailer design concept. This unitized the undercarriage with the side structure to form a single-acting body Also in the 1940’s, construction began on the new plant on Leech Avenue in Sioux City, Iowa.

Wilson Persinger assumes the management of Wilson Trailer Company following the untimely death of his father Clarence.

Wilson Persinger announces a plant expansion program to include construction of a new plant to manufacture livestock and grain trailer component parts. The company is soon able to increase trailer production 20% as a result of continuous flow of materials to the production lines. In 1959, the manufacturing facilities of this plant are doubled in size. In 1964, the entire plant will double in size once more, and a Production and Engineering office will be added.

Wilson Trailer had already been using some aluminum components in the construction of their trailers, but with new extra-strength aluminum alloys Wilson was able to introduce the AL-100 and ADCL-100 all-aluminum livestock trailers in 1964. Specially designed and engineered extrusions and castings allowed Wilson to take full benefit of the weight advantages inherent in aluminum.

Wilson develops the G-300 Grain trailer, making it necessary to further expand production facilities. The G-300 features “Strongated” construction. The term, originated by Wilson, refers to the unusual method used to form the stronger sides to these trailers. In 1966, Wilson completed development of, and began production of their first grain hopper trailers. Again in a move to bring more lightweight aluminum models to the market, the AG-300 aluminum version was introduced in 1968, and in 1976 the AGH-500 Aluminum Hopper bottom trailer made its debut.

Also in the 1960’s, Wilson launched the OF-100 steel outside frame flatbed trailers to the ever-growing line of trailers. These trailers later evolved into the Combination Steel and Aluminum CF-900 flatbed and CFD-900 drop-deck trailers. With the lightweight, long-lasting aluminum components, the trailer’s ability to carry larger payloads with much lower maintenance costs made these trailers very popular. The “combo” soon became the standard for the industry. In the mid 90’s, Wilson ushered in the ACF-300 All-Aluminum flatbed and in 2006 they released the ACFD-300 All-Aluminum drop-deck into production.

Livestock trailer sales continued to prosper, and Wilson Trailer made the decision to build a separate facility in Yankton, SD to produce livestock trailers. The 84,383 sq. ft. building was enlarged in 1998 to handle increased production of gooseneck livestock trailers an additional 53,000 sq. ft. With sales of Wilson’s livestock semi-trailers dominating the market and the growth of their popular gooseneck trailers, in 2015 it became necessary to enlarge the plant an additional 35,000 sq. ft. With a total 172,384 sq. ft. of production floor space, the Yankton plant now produces the flagships of today’s livestock trailer industry.

The eighties and nineties saw an increased use of personal pick-up trucks and the desire to haul it “myself.” In 1989, Wilson began to market the aluminum PSGN models to this demand. The gooseneck models have proven themselves as versatile, long-lasting values.

The grain trailer industry was introduced to the aluminum double wall hopper. Wilson’s Pacesetter model featured full-length one-piece side skins on the outside and the inside. Sidewall drain ports along the lower side rails and between each set of side posts allowed air to circulate in the sidewall cavity.

The concept of combination steel/aluminum and all aluminum flatbed/drop deck trailers had gained in popularity, so Wilson Trailer opened a 100,000 sq. ft facility in Moberly, MO to meet the demand. This building produces trailers known for their high-capacity ratings and long-lasting durability. The facility also handles additional grain trailer production during peak demand periods. Today, Wilson flatbed and drop deck trailers maintain a reputation, in a highly competitive industry, for being the most durable and longest lasting with the lowest operating cost.

In 1996, Wilson developed and patented a revolutionary hopper trap opener called the RollerTrap or more commonly known as the “strap trap”. The trap opener, made of corrosion resistant aluminum and stainless steel, eliminates obstructions below the trap frame and the need for heavy gearboxes. The uncomplicated design uses two flexible straps to pull the door open and closed with minimal effort. A standard feature on every grain trailer, the RollerTrap has proven to be one of the industry’s more popular innovations.

Through series of government subsidies and mandated consumption levels, production of corn-based ethanol rose dramatically and distillers grains, a byproduct of ethanol production, had become an abundant resource for livestock feeders. Wilson Trailer developed the Patriot self-unloading belt trailer to meet the need of transporting the distillers grains from the distillery to the feeder. The Patriot belt trailer proved to be the most popular trailer for this market.

Construction began on a new 64,268 sq. ft. plant in Lennox, SD to allow production of gooseneck livestock trailers to be split out from the facility in Yankton. However, those plans abruptly changed with the passage of ethanol subsidies and farmers beginning to haul their own grain. Demand for grain trailers grew substantially, therefore it then became necessary to turn this facility into additional grain trailer production. In 2011, the facility was enlarged an additional 76,884 sq. ft. for a total of 141,252 sq. ft. of efficient production space. Today, Wilson grain trailers are produced in Lennox, SD, Sioux City, IA and Moberly, MO and are some of the most preferred, top-selling grain trailers in North America.

Wilson Persinger passed in May of 2010. Mr. Persinger led the company through many innovations and industry advancements. His 30+ years at the company’s helm advanced Wilson Trailer to be one of the top trailer producers in the country. Wilson’s sons, Bill and John have assumed the shared positions of Co-CEOs.

Back in 1890, hammering and shaping metal into components for his own brand of wagons and carts is how the ambitious Frank Wilson set about forming Wilson Trailer Company. 125 years later, Wilson Trailer is competing on a global market with transportation products well known for their design, performance, low maintenance costs and wise use of aluminum. Although proud of their heritage and longevity, Wilson Trailer continually looks for ways to improve so the company’s success continues for generations to come.

Back in the day, Wilson Trailer’s downtown location on the hill used to overlook one of the busiest stockyards in the nation – It was a prime location for a trailer service center, especially livestock trailers. Today, with the stockyards long gone, the need to relocate the parts and service center to a location with better access was recognized and construction was finished in 2019 on a new addition to the Sioux City grain trailer manufacturing facility. The new location, on the company headquarters campus, has direct access off Interstate 29 and allows customers to drop off their trailers for service or pick up them up 24-hours a day. The new service and parts facility added a 16-bay, 27,000 sq. ft. service shop, which is home to the area’s only frame straightener. The new addition also added 22,000 sq. ft. of warehouse space to the grain trailer manufacturing facility and streamlined fabricated parts directly from production to the new service area.