The most preferred grain trailer in North America! Up and down the highway and in and out of the field is just what the Pacesetter is designed to do – Premium performance when and where you need it.

The “original” sloped double wall aluminum grain trailer by Wilson Trailer is available in both widths and ALL lengths. Experience the reliability of a proven and tested design, rather that the trials of others attempting to duplicate it.

Realize the Patriot’s full hauling potential from season to season with products like corn, potatoes, gluten, hay cubes, gravel and limestone – All unloaded in just a few minutes. The Patriot is standard with the best features and it has all the available options necessary to make this trailer meet your hauling needs.

Lightweight, long-lasting aluminum and Wilson’s tested tough construction results in a trailer able to endure varying extremes and road stresses, while achieving some of the industry’s best load capacities.

With its 15’3” of ground clearance and a full 10’ of side to side swing distance, the AgriLite tender trailer by Gem-L gives you more clearance and flexibility to move up to 6,000 pounds of fertilizer per minute.

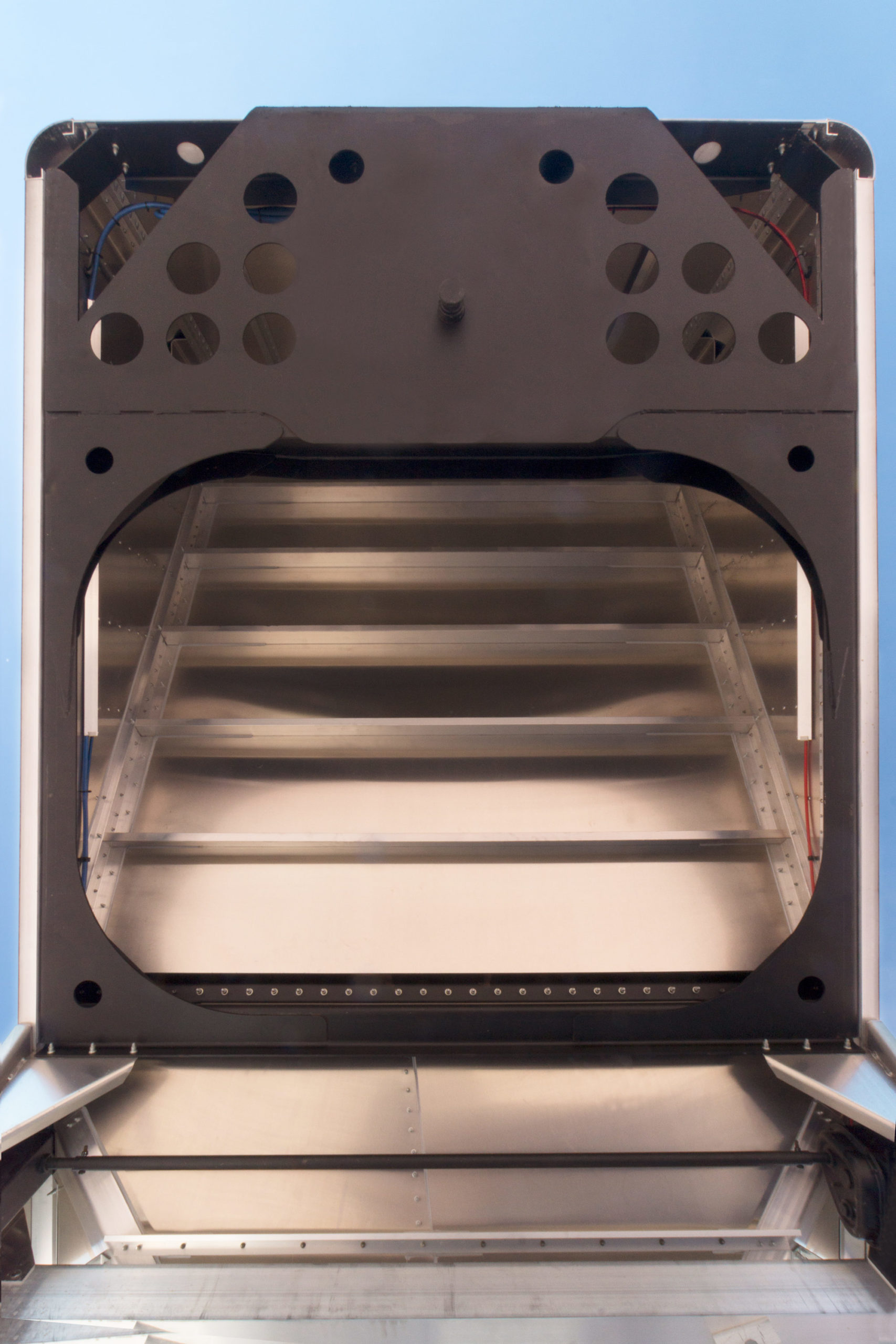

The concept of creating additional capacity for the livestock hauling industry was developed by the minds at Wilson Trailer in the mid 1950’s and their drop center livestock trailer has led the industry in user confidence and sales ever since. The Wilson Silverstar offers multi-level hauling for a variety of livestock types with the utmost concern for their safety and the bio security of the trailer. Wilson is THE LIVESTOCK BRAND!™

Stockmaster semi-trailers are available in straight floor or shallow drop for greater compartment height. Different multi-level static deck configurations can be added - or consider adding hydraulic lift decks offering less stress for animals and easier cleanout for operators. Wilson pays the best attention to animal safety by eliminating areas which cause scrapes and bruising and they build-in better bio security by eliminating areas that retain animal waste. Available in either punch or slat style, the trailers are completely fastened, allowing the trailer to flex when needed. You will appreciate the lower cost of operation by not having to repair broken welds.

Load and unload almost anywhere with the Stockmaster ground load semi livestock trailer. Rugged, long-lasting riveted aluminum construction gives the trailer a longer, more useful life with lower maintenance costs.

The Roadbrute straight deck and drop deck flatbeds have played a prominent role in making the combination steel and aluminum flatbeds as popular as they are today. Outstanding weights, unbeatable capacities, and outstanding durability is what the Roadbrute brings to the market at competitive prices. This is a workhorse of trailer that is also available with a beavertail rear or in a super-b configuration. FEATURES • Strong aluminum floor • Patented side rail and securement design • Full width aluminum cross bars • Weight savings near 1,500 lbs.

The Premier flatbed and drop deck trailers are true all-aluminum trailers offering corrosion free hauling with maximum hauling capacity ratings at 80,000 lbs. The Premier flatbed features a full-length, non-spliced main beam on trailers up to 48’ long and the Premier drop deck successfully makes the transition from the 1-piece aluminum main beam to the aluminum gooseneck with a strong and durable attachment. FEATURES • Strong aluminum floor • Patented side rail and securement design • Full width aluminum cross bars • Weight savings near 300 lbs.

The Foreman gooseneck livestock trailer offers you all of Wilson Trailer's great standard features plus the full complement of Wilson's available options – You have the freedom to equip your new stock trailer to your exact specification. Choose from a wide variety of side patterns, rear ends and divide gates. Add even more hauling capacity to your livestock trailer by ordering our double deck option. Wilson is THE LIVESTOCK BRAND!™

The Ranch Hand 5700 line of aluminum gooseneck livestock trailers has all the essential features in an affordable package. The trailer is available in 5 popular lengths with a limited but convenient list of optional equipment. The Ranch Hand is also available in a bumper hitch. Wilson is THE LIVESTOCK BRAND!™

The Roper is designed to appeal to three niche markets, the rancher, the showman and the rider. Carry equipment to the feedlot, the range, the cattle show, or gear it up for trail riding. They are all available in gooseneck or bumper hitch models plus we have an exciting new line of horse trailers.

Pacesetter

STANDARD FEATURES

- Open-design king pin area

- Full length inside skins

- Deeper front, rear and side channels

- Recessed stop/turn lights in rear header

Commander

STANDARD FEATURES

- Open-design king pin area

- Full length inside skins

- Deeper front, rear and side channels

- Recessed stop/turn lights in rear header

Patriot

STANDARD FEATURES

- Side walls are smooth and double walled

- Enclosed floor pan

- Side vent ports

- Full width rear dust shield

Super-B

STANDARD FEATURES

- Open-design king pin area

- Full length inside skins

- Deeper front, rear and side channels

- Recessed stop/turn lights in rear header

Agrilite by GEM-L

STANDARD FEATURES

- Fold-over conveyor arm

- Electric controls

- Remove the conveyor in under an hour!

Silverstar

FEATURES

- Riveted construction

- Superior ventilation

- Superior gate construction

- Counterbalanced ramp

Stockmaster PSADL / PSAL

Stockmaster-PSAGL

FEATURES

- Move animals almost anywhere they need to go

- Riveted construction

- Superior ventilation

- Superior gate construction

Roadbrute

FEATURES

- New aluminum floor

- New patented side rail and securement design

- New aluminum crossbar design

- Weight savings near 1,500 lb.

- Corrosion resistant king pin

Premier

FEATURES

- Aluminum floor

- Patented side rail and securement design

- Aluminum crossbar design

- Weight savings near 300 lb.

- Drop deck is a "true" all aluminum trailer

- Flatbed has a 1-piece main beam front to rear

- Capacities up to 80,000 lb.

Foreman

FEATURES

- New patented rear door slam catch

- Enclosed overhead wiring

- Smooth interior walls

- Heavy-duty and fully framed gate

- Riveted Construction

Ranch Hand

FEATURES

- Aluminum sub frame

- Patented rear door Slam Catch

- Full-length running boards

- Heavy-duty construction

- Superior full-framed gate construction

Roper

FEATURES

- Available in both punch and slat style sides

- Patented rear door slam catch

- Enclosed overhead wiring

- Smooth interior walls

- Heavy-duty and fully-framed gates

- Riveted construction